Boiler DoctorEXPANSION TANKSWhen water is heated it expands, when it cools it shrinks, an expansion tank allows this to take place without adding or losing water. The amount of water determines the size of the tank.The history of expansion tanks started with the need to raise the boiling point, to eliminate corrosion from oxygen and to eliminate the need to add water. The early hydronic system held a very large amount of water and required a large expansion tank.

Can Expansion Tank Be Installed Upside Down Trailer

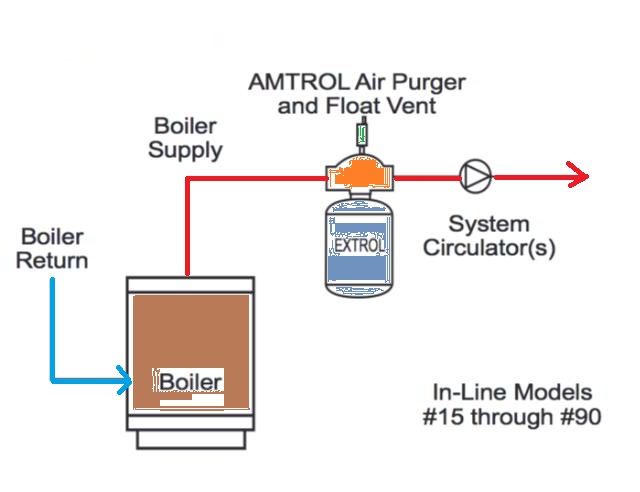

They also needed to be mounted above the boiler and plumbed to trap the air coming out of the boiler.The insulating values of today's homes has greatly reduced the size of the boilers required. Very few homes need more than the smallest expansion tank.The expansion tank is made out of steel and should not be screwed into a copper fitting, if you must install it on copper put a brass coupling between them.The mistake most often made is installing the tank upside down. The pipe fitting must be on the top.

The tank is made out of very thin steel and any air trapped in it will greatly shorten it's life.Do not place the tank to close to the pump, it can cause the fill valve to pull in more water than the system needs and cause high boiler pressure.When the tank is installed upside down it can be the source of noise in the system. When the system heats up, the bladder moves up, allowing the tank to hold air. When the system cools, the bladder moves down forcing the air into the system to circulate and cause noise.

Also when water is heated it releases other gases besides air and these can be corrosive to the tank.AIRHOTCOLDZONE VALVES:Installing the zone valves on the return manifold will reduce their operating temperature and will make them last longer. It will also reduce complaints of noise from zone valves closing to fast. Some zone valves can be forced open by the pump. If placed to close to the pump, this will cause complaints of to much heat at times.FLOAT VENTS:Float vents should be cast brass and be installed as shown only. This is the only vent needed on a radiant system. On a baseboard system the only other vents needed are on the downstream side of the baseboards.Many boilers have a baffle built into them to trap air. If the boiler has a tapping on the top of it marked air vent, it must have a float vent installed in it, in addition to the one on the return manifold.PRESSURE RELIEF VALVE or POP-OFF:The pressure relief valve is a very important thing.

If the boiler has a tapping marked for it, you must install it there. Follow the manufacturer's instructions. The pressure relief valve on top of the boiler or as close to the top of the boiler, and the feed water must be on the bottom. The reason for this is that if the relieve valve goes off, the cold feed water comes in the bottom of the boiler and helps to keep it from getting to hot and making steam. If the fill valve is put on top of the boiler, the feed water will short circuit and go directly out the relief valve, allowing the bottom of the boiler to get to hot and continue making steam.I have seen cast iron boiler sections cracked because the feed water was on top of the boiler.